Explore services

For large orders (2,000-5,000 or more), Packlane Plus offers a variety of custom packaging solutions and project assistance with pricing and service you’ll love.

Free expert consultations

Whether you’re new to custom packaging or an old pro, our team of packaging experts can guide you through the process with a free consultation.

Custom styles & materials

Not finding what you’re looking for on our website? We’ll source the custom styles and materials your packaging needs from custom bags to void fill.

Design & prototyping services

Make your packaging design more efficient and cost-effective with our design and prototyping services.

Protective packaging

Prevent damage to your product with custom inserts and foam designed right down to your exact specifications so that your product always arrives safely.

Custom packaging products

Got a large order? Packlane Plus can meet all of your custom packaging needs. We’re your one-stop shop for everything from custom boxes to flexible packaging to tissue paper.

Rigid paper mailers (2,000 MOQ)

Made from 100% recycled paper for flexible and lightweight items.

Custom Tape

Custom packaging tape adds a nice finishing touch to your boxes.

Large order add-ons

Box orders of 2,000 units or more may qualify for custom dividers, inserts, tape and void fill.

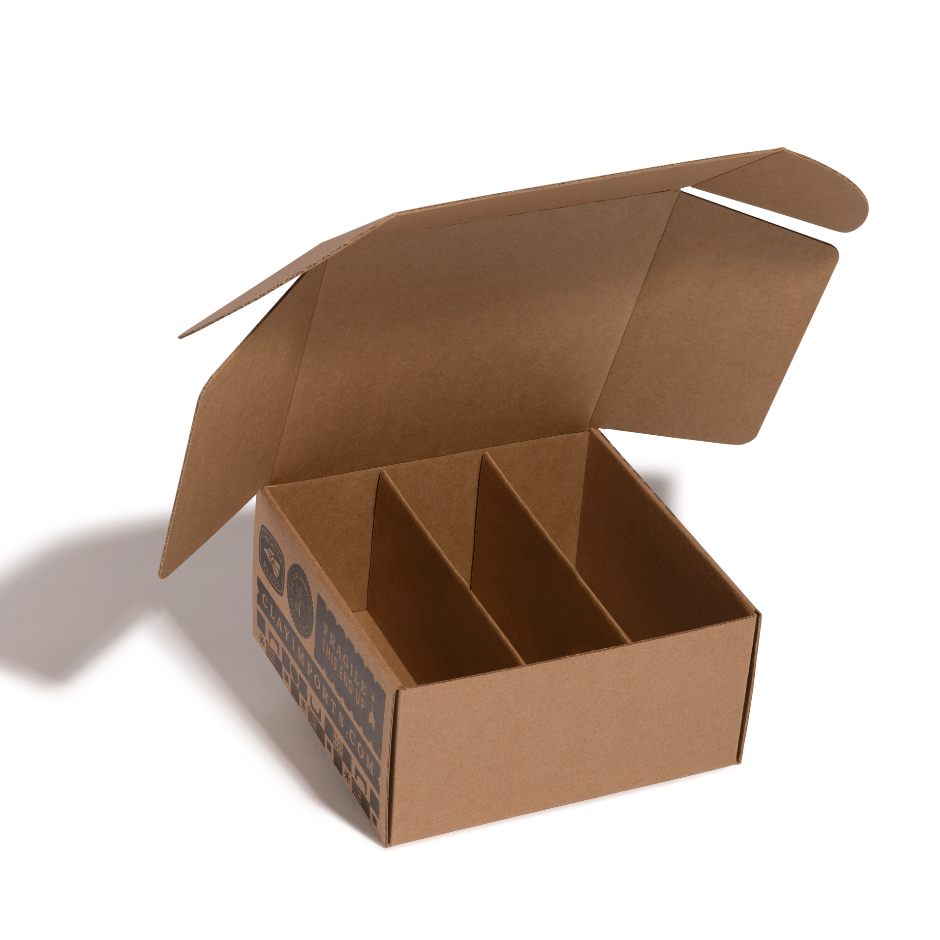

Box dividers

Custom dividers provide additional protection while shipping.

Unprinted Packaging Tape

Seal with confidence when you use our packaging tape products

Void fill

Void fill is sustainable, 100% recyclable, and compostable.

Solid-Color Tissue Paper

High-quality and Earth-friendly solid color tissue gives cushioning and perfect presentation

Real reviews from real customers

“In the past 8 months, we have began using Packlane for large volume orders of 30,000 units at a time. It has been a pleasure working with them as they’re a full end-to-end solution for our corrugate. They have helped us identify opportunities to produce closer to our warehouse and limit the cost of transport. Perhaps more importantly, their communication is accurate. To date, Packlane has delivered POs on the delivery date agreed upon at order placement.”

Emma Nelson

VP Operations, MUDWTR

“My company has used packlane for our custom boxes for the past 3 years and couldn’t be happier! I have been in discussions for our box needs with several other companies when I started searching for a distributor and none came close to Packlane in pricing, service, or quality. I worked closely with Lyza at Packlane and felt confident throughout every step of the way. We have grown our box order by nearly 7,000 units from when we first used them and firmly recommend Packlane to anyone who has custom box needs. If you are looking for the best possible pricing, service, and product quality, do not look elsewhere – Packlane is simply the best!”

Alex Bristol

VP of Operations & Product Development, Now and Forever Studios

“First impressions are everything – particularly for a startup like Peekaboo Ice Cream trying to establish its brand voice. We want to reach consumers before they even taste our ice cream (with hidden VEGGIES) and Packlane has been such a valuable asset in allowing us to interact with the Peekaboo consumer from the moment they see our box sitting on their doorstep. The ability to have this tool of communication with no order minimums and competitive pricing means we get to grow with Packlane, too. We started with a small order of 20 branded shipping boxes and then added mailer boxes for swag and now have increased our orders to the hundreds. There is no reason to ever go anywhere else for shipping products.”

Jessica Weiss Levison

CEO, Peekaboo Ice Cream

Kelsey Moreira

CEO, Doughp Cookie Dough

“SendAFriend’s high volume needs have been met with Packlane’s competitive pricing and extremely quick turnaround. Similar pricing to Packlane’s would require us to go overseas for custom packaging, which would greatly increase our lead time and place limits on our output capabilities. On top of that, their pricing breaks have continued to increase our margins with each order, which has only made our business more profitable.”